We probably should have anticipated that putting a huge knob on the rotary switch would increase the mechanical stresses on the switch. The switch held up to a few hours of vigorous use by the many children at STEAM Maker Festival, and then started showing signs of failure. At one point I caught it acting as an 11-position rotary switch, instead of the 10-position switch it is supposed to be. The detents still lined up with the panel markings, but some (!) of the functions were offset by one position. Then, the end stop stopped working, leaving the knob free to go all the way around in one direction but not the other. Finally, the switch stopped working entirely, making no connection at any position.

We had to alter the software to ignore the rotary switch and stay in one mode (the keyboard visualization with waterfall effect) for the rest of the event.

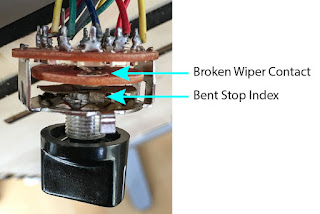

Back in the lab, I pulled out the rotary switch for failure analysis. I found two problems, explaining the observed symptoms. The end stop relies on a round sheet metal plate with a tab bent down. That plate was bent, leaving the tab at an angle, so it could ride up over the stop in one direction but not the other. It's easy to see how the plate could get bent when the knob is slammed against the stop. The other problem was that the moving contact that wipes over the ten fixed contacts was broken off. I found the contact loose in the housing.

I speculate that the stop plate bent first. The wiper contact then fell off the end of the fixed contacts into the gap between the first and tenth contact. When the knob was returned to a normal position, the wiper contact had to ride up onto the first or tenth fixed contact, which it was not designed to do. It was able to survive a few such transitions before breaking off.

So, we need to find a more robust rotary switch or else go back to a much smaller knob.

Wednesday, December 9, 2015

Setup and Configuration at STEAM Maker Festival

Organ Donor Opus 1.2 was set up in record time for the STEAM Maker Festival at the Del Mar Fairgrounds. We had just three hours on Friday and an hour and a half on Saturday morning before the event, for a total of 4.5 hours. The previous record was about 6 hours.

We were able to drive both vehicles right up to the installation site, so very little time was spent carrying parts back and forth. Plus, Richard was there to help.

Over the last few installations, Abraxas has developed a more systematic procedure for placing the air tubes between the wind chest and the pipes. She starts by sorting the tubes by length, and puts the shorter ones in the back. This results in a more orderly arrangement, and less struggle to make all the tubes reach.

Since the last installation, Paul has created a software assistant for configuring the system to match the installation of the tubes. For past installations, we have written the mapping from wind chest to pipes in a notebook, painstakingly checked it over manually for errors, and then manually pressed keys on the manuals to send the programming sequence to the MTP8 MIDI-to-parallel converters in the wind chest. Any error in the latter procedure meant starting over. Now, we press keys on the manuals to tell the software assistant about the mapping. Any duplicate entry is immediately detected and easily corrected. When all the data has been entered, sending the programming sequences to the MTP8s is fully automatic.

The photo shows the screen of the configuration assistant after all the mappings have been entered. I wanted to record the data before doing anything else, just in case there was a problem.

We were able to drive both vehicles right up to the installation site, so very little time was spent carrying parts back and forth. Plus, Richard was there to help.

Over the last few installations, Abraxas has developed a more systematic procedure for placing the air tubes between the wind chest and the pipes. She starts by sorting the tubes by length, and puts the shorter ones in the back. This results in a more orderly arrangement, and less struggle to make all the tubes reach.

Since the last installation, Paul has created a software assistant for configuring the system to match the installation of the tubes. For past installations, we have written the mapping from wind chest to pipes in a notebook, painstakingly checked it over manually for errors, and then manually pressed keys on the manuals to send the programming sequence to the MTP8 MIDI-to-parallel converters in the wind chest. Any error in the latter procedure meant starting over. Now, we press keys on the manuals to tell the software assistant about the mapping. Any duplicate entry is immediately detected and easily corrected. When all the data has been entered, sending the programming sequences to the MTP8s is fully automatic.

The photo shows the screen of the configuration assistant after all the mappings have been entered. I wanted to record the data before doing anything else, just in case there was a problem.

Thursday, December 3, 2015

Organ Donor ready to pack up for STEAM Maker Festival

Organ Donor Opus 1 will be exhibited at STEAM Maker Festival at the Del Mar Fairgrounds on Saturday, December 5, 2015. On Thursday night, all the parts are staged to be packed into two vehicles for transport to the fairgrounds and assembly on Friday afternoon. Here's what that looks like.

Subscribe to:

Posts (Atom)